What makes Modern Glass different from other companies?

We undertake complex projects

Really complex projects

Really complex projects

What makes Modern Glass different from other companies?

We undertake complex projects

Really complex projects

Really complex projects

About the company

Advantages

Superb production capabilities

Top quality

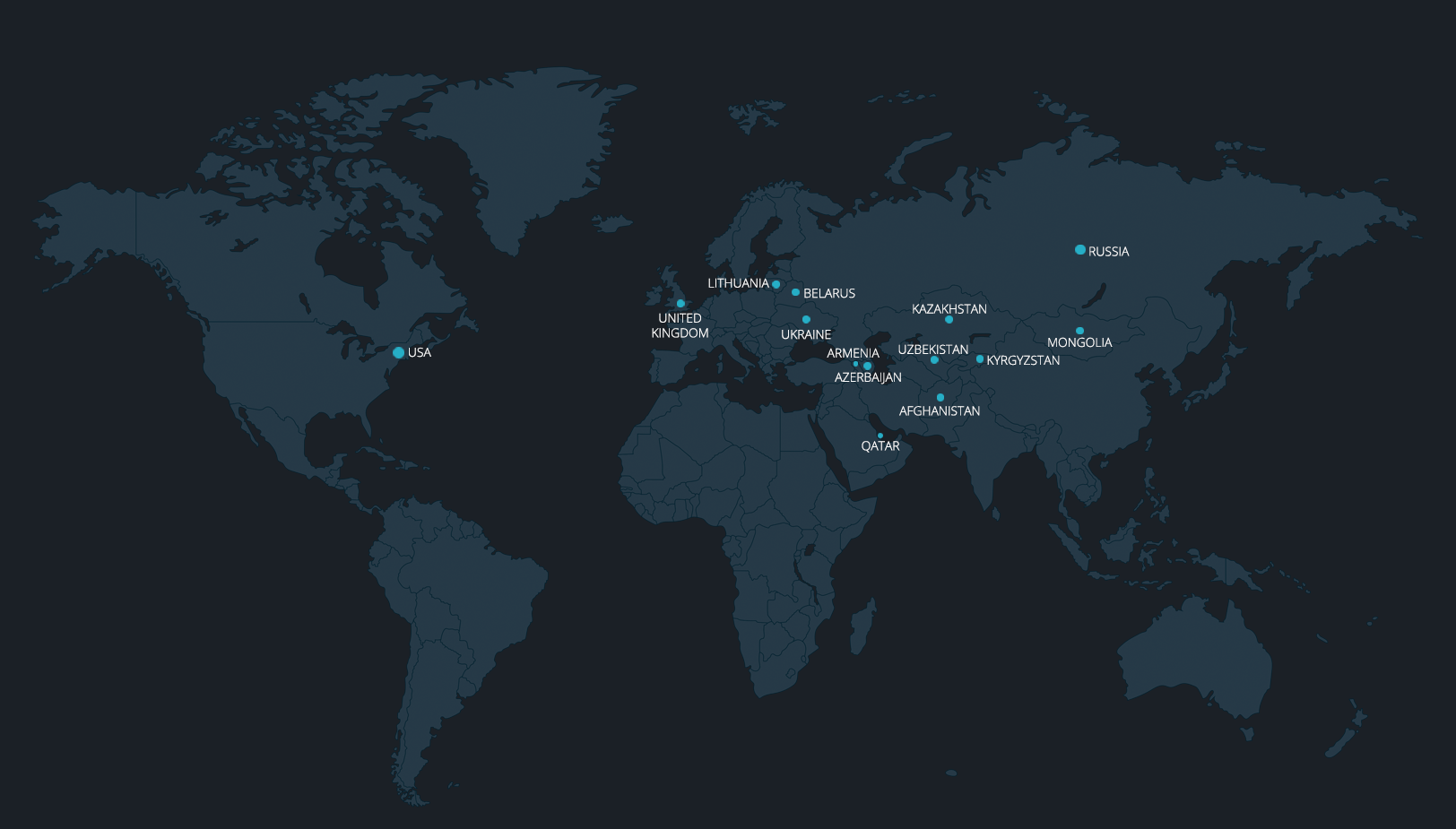

Worldwide shipping

Top-notch experts

Automatic notification system

Fast order fulfillment

Projects in progress

Russia’s largest flat glass processing site

Cutting-edge European equipment combined with thorogh quality control

Development, testing and application of innovative technologies

3 autoclaves,

5 tempering furnaces,

5 assembly lines of insulated glass units

5 tempering furnaces,

5 assembly lines of insulated glass units

Output: 100,000 sq m

per month

Jumbo-size 3,210х6,000 mm

glass products manufacturing capability

glass products manufacturing capability

Shipping to 90 cities of Europe and Asia

Russia’s only plant to produce Pyropane glass for AGC company

3 types of printing on glass: roller, silk-screen and digital

ISO 9001 certificate — international requirements for quality management

projects

Top 5