PAINTED

Painted glass is tempered glass with glass-ceramic coating, resistant to exposure and belonging to safety glazing group. During tempering the paint is fused into the glass surface to become its inseparable part.

Painting methods: roller, silk-screen, digital. These painting methods are applicable for various types of glass in single products, IGUs and triplexes.

Modern Glass produces painted glass under MG Color (roller and silk-screen printing) and MG MultiColor (digital printing) brands.

MG Color

Monochrome painting by roller or silk-screen method

Advantages

- Safety, high resistance to mechanical and thermal exposure

- Durable in all climate conditions

- Colorless and colored opaque coating, opacity variation

Roller printing

Paint is applied when the glass passes between painting line metering and pressure rollers

Advantages

- Uniform printing on glass of any size

- Changing ink density by adjusting roller speed and type

- High performance

Production capabilities

Max. size:

Max. size:2,600х6,000 mm

Thickness:

Thickness:4-19 mm

Silk-screen printing

Decoration process where an image is formed by forcing ink through a silk stencil mesh

Printing is done on an automatic machine for on-glass printing with glass-ceramic paint

Advantages

- Wide range of shades from Ral Classic catalog

- Creating an opaque image

- Use of ‘metallic’ color paints

- Minimal cost for a large number of copies, as compared with digital printing

- High performance

Production capabilities

Max. size:

Max. size:2,200х5,000 mm

Thickness:

Thickness:4-19 mm

MG MultiColor

Multi-color digital on-glass printing using a special-purpose printer

Advantages

- Unlike silk-screening, there is no need to make an expensive stencil mesh

- Light transmission variation

- Multi-color printing

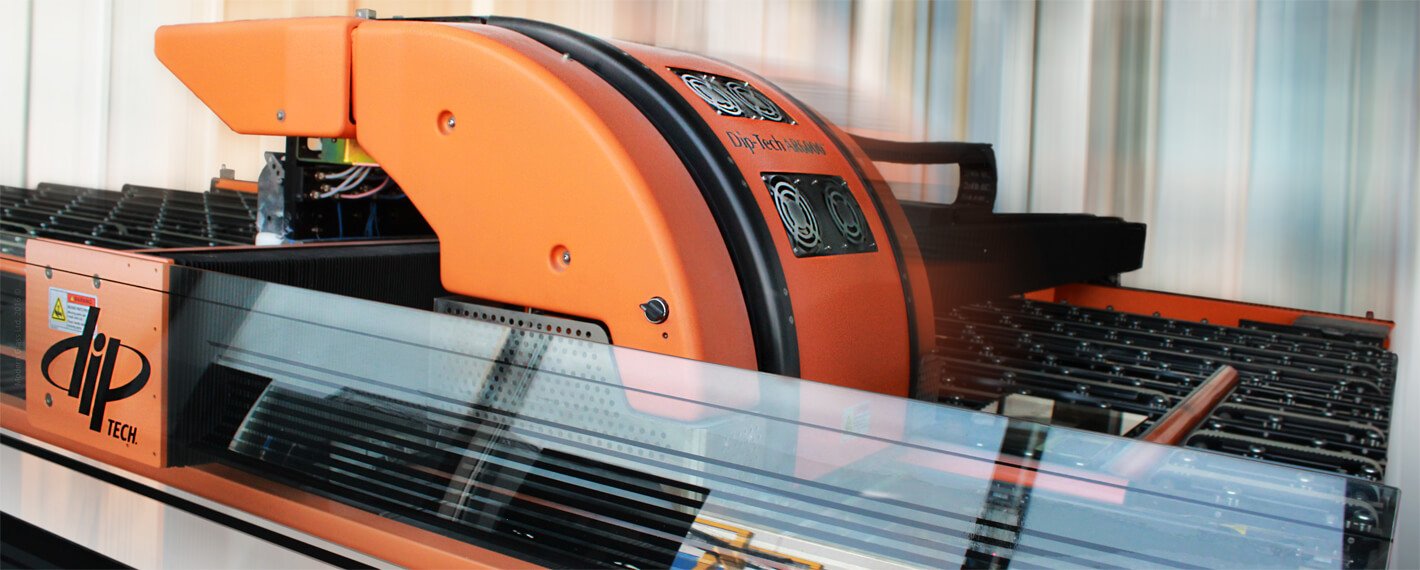

Digital printing

Printing with an inkjet printer with subsequent heat treatment, whereby an image is sintered to glass surface, acquiring physical characteristics comparable with the glass itself

The printer uses ink consisting of ground glass for sintering with the product, metal oxide for coloring, solvent for exposure resistance

The ink is of 6 basic colors: white, blue, green, orange, red, and black

Advantages

- An extensive ink palette in the form of pre-mixed or digitally mixed colors

- Resistance to weather conditions, UV exposure, or scratches

- Non-toxic ink makes it possible to process glass without harm to the environment

- Creation of additional visual effects to solve design tasks of any complexity

Production capabilities

Source file formats: pdf, eps, jpeg, tiff, bmp

Source file formats: pdf, eps, jpeg, tiff, bmp

Adjustable coating density

Adjustable coating density

Print resolution:

Print resolution:up to 720 dpi

Max. size:

Max. size:3,200х6,000 mm

Thickness:

Thickness:4-19 mm