LAMINATED

Triplex is multilayer laminated glass consisting of two or more panes bonded with a special film. After an impact the glass may crack, but splinters will remain on the laminating layer, thus reducing the risk of people getting an injury and glass falling out.

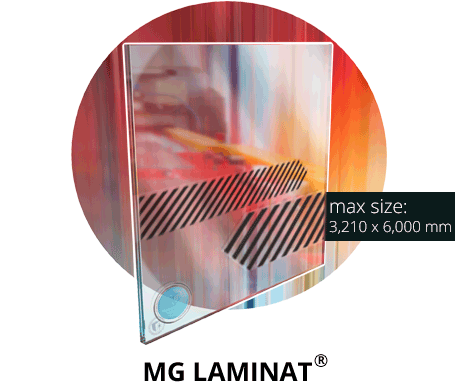

Modern Glass produces triplex under the MG Laminat brand.

MG Laminat applications

- Translucent structures with high risk of glass breakage and injury

- Building elements: facade glazing, windows, balcony glazing, glass roofs, glass doors, fencing and partitions

- Interior: stair steps, glass tables

- Transport: cabin glazing

- Special applications: glazing for sports facilities, aquarium glass, external elevators, floor structures, underwater rooms, UV-proof glazing, bullet-proof glass, and fireproof glass

MG LAMINAT ADVANTAGES

Safety: in case of destruction glass is not scattered

Sound insulation: the film keeps noise away

Functionality: heat-saving and sunlight protection

Protection against mechanical impacts, intrusion and burglary

Resistance to corrosion, attrition, atmospheric precipitation

Protection against ultra-violet radiation

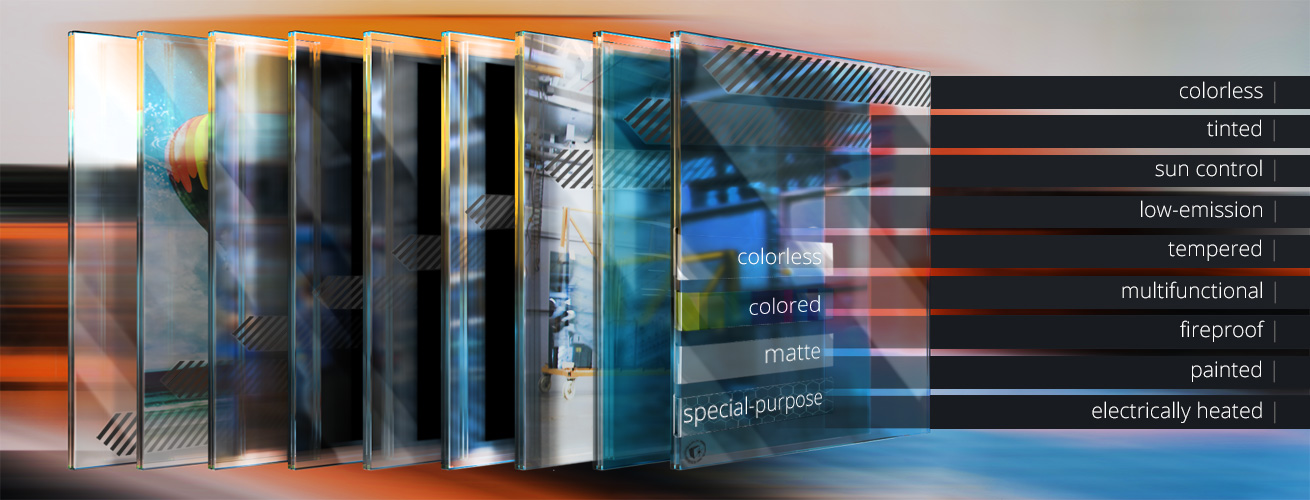

MG LAMINAT TYPES

Rough triplex

Tempered triplex

Multifunctional triplex

Bullet-proof triplex

Soundproof triplex

Painted glass triplex

1. Roller painting

Max. size: 2,600х6,000 mm

2. Silk-screen printing

Max. size: 2,200х5,000 mm

3. Full-color digital printing

Max. size: 3,210х6,000 mm

Electrically heated triplex

Max. size:

3,000х6,000 mm

Electrochromic (smart) triplex

Max. size

1,500х3,000 mm

Fireproof triplex

Fire-resistant Pyropane glass can be used in triplex subject to approval by AGC company

MODERN GLASS PRODUCTION CAPABILITIES

Max size:

Max size:3,210х6,000 mm

Thickness:

Thickness:up to 100 mm

Max weight:

Max weight:2,500 kg

MG Laminat production specification

MG LAMINAT PRODUCTION MATERIALS

Glass

Film types

SENTRYGLAS FILM ADVANTAGES