Variable transparency glass

Variable transparency glass (smart glass) is multi-layer laminated glass capable of changing its optical properties from opaque to transparent state under the influence of electric current. With power supply off the glass is opaque, and with power on it becomes transparent.

Modern Glass produces variable transparency glass under MG Smart brand.

MG Smart applications

- Projection and advertizing screens

- Confidential rooms

- Exhibition booths

- Shop windows

- Office and room partitions

- Facade glazing (sun protection)

- Shower cabins

- Doors

MG Smart advantages

Max size:

Max size:1,500x3,000 mm

Thickness:

Thickness:up to 100 mm

Max weight:

Max weight:1,000 kg

For MG Smart production we use liquid-crystal variable transparency film (PDLC technology). The liquid crystal layer is located between two special-purpose films.

MG Smart technical characteristics

- Energy consumption: 7 W / sq m

- Supply voltage: 110 volts AC (provided by a special transformer)

- Transition from opaque to transparent state takes less than 1 sec

- Operating temperature range: from –25 °C to +60 °C

- Light transmission: up to 80% both in transparent and opaque state

- Transparency: more than 80% in transparent state, less than 8% in opaque

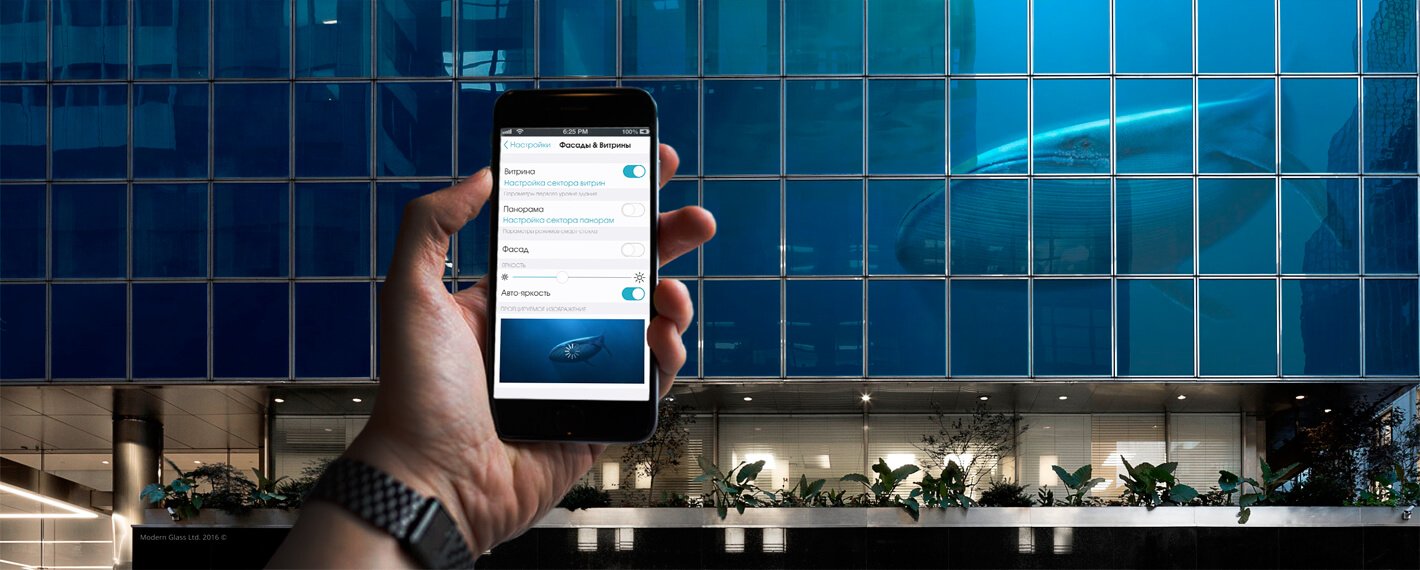

Operating modes of MG Smart control system

- Stationary switch

- Remote control

- Smart Home compatibility

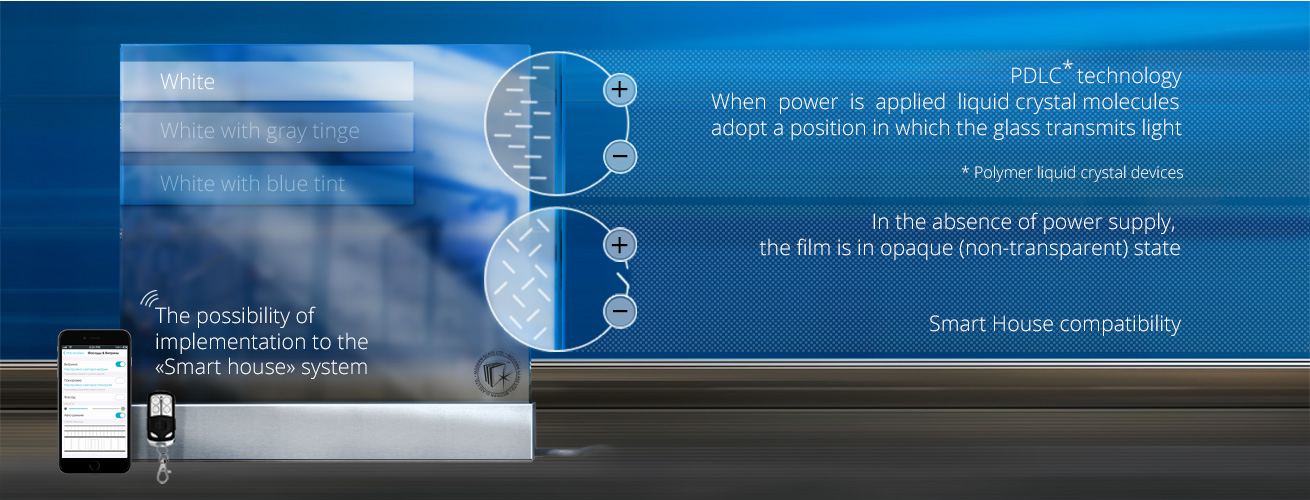

PDLC technology

The film structure consists of two transparent polymeric films with a liquid crystal layer in between.

Opaque

The film at rest has an opaque milky-white color. Liquid crystals are located chaotically, scattering the light passing through.

Transparent

When 110 V, 50 Hz voltage is applied to the film, liquid crystals along the electric field lines recombine, the film begins to permit all light through and becomes transparent.

MATERIALS FOR MG SMART PRODUCTION

Glass

• colorless

• tinted

• sun control

• low emissivity

• tempered glass

• multifunctional

• fireproof

• painted

Film

• white

• white with a shade of gray

• white with a shade of blue

Producer: DMDisplay (Korea)

Please note: variable transparency glass production is temporarily suspended, until about 2021.